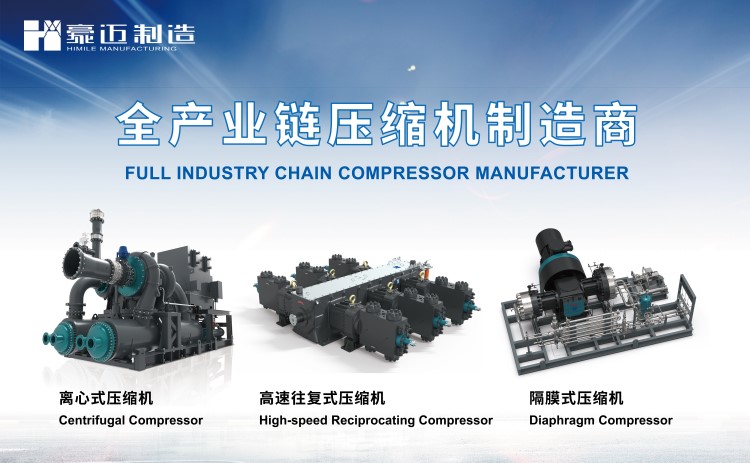

Halma has a full range of centrifugal compressors, reciprocating compressors, diaphragm compressors with independent intellectual property rights, and is one of the top ten brands of domestic compressors, with nearly 20 years of experience in high-end compressor processing and manufacturing, providing customers with professional gas compression solutions. It has set up three major R&D centers in the world, has a professional design team, and has first-class core technology design capabilities such as aerodynamics, rotor dynamics, engineering thermodynamics, and fluid mechanics. Relying on the group's strong manufacturing capacity of the whole industry chain, it can provide one-stop services from R&D, design, casting, processing, to assembly and testing.

Halma centrifugal compressor, with excellent mechanical structure design, can provide continuous, stable, oil-free, high-quality compressed gas under the minimum maintenance workload, business involves standard units, air separation units, process gas compressor units, station general contracting and waste heat recovery and other directions, customers throughout the petrochemical, metallurgy, air separation, chemical, steel, coal, electric power, biological fermentation, rubber, textile, glass, electronics, lithium battery, automobile, CCUS and other industries, and has been exported to Central Asia, Southeast Asia, Europe, more than 10 countries and regions such as South America; Halma high-speed reciprocating compressor is used in natural gas extraction, storage and transportation scenarios such as wellheads, gathering and transportation stations, and offshore platforms; Halma diaphragm compressors are used in fine chemicals, gas industry, hydrogen energy and other fields. Halma actively promotes the formulation of compressor industry standards and the popularization of first-class energy efficiency stations, practices the new concept of green development, and provides users with safer, more reliable and more energy-saving domestic high-end compressor products.