Founded in 1971, Xinxing Jihua Group is a comprehensive metal products processing enterprise with advanced scientific research and development capabilities of special steel pipes, centrifugal ductile iron pipes and steel grating

Xinxing Pipe Co., Ltd. was established by Xinxing Jihua Group Co., Ltd. (formerly Xinxing Pipe Group Co., Ltd.), formerly known as the third-line army steel plant founded in 1971, and was issued and listed in 1997, with a total share capital of 3,643,307,361 shares, of which Xinxing Jihua Group Co., Ltd. holds 45.38%.

Over the years, under the guidance of the strategic idea of "steel-based, cast-pipe-led", the company has continuously extended and improved the industrial chain and value chain, and formed Wuhu Xinxing Pipe Co., Ltd., Taojiang Xinxing Pipe Fittings Co., Ltd. and Huangshi Xinxing Pipe Industry Co., Ltd. with North China as the core, covering East China and Central South China, Sichuan Chuanjian Pipeline Co., Ltd. and Xinjiang Jinte Steel Iron Co., Ltd. covering southwest and northwest Sichuan Province Chuanjian Pipeline Co., Ltd. and Xinjiang Jinte Steel Iron Co., Ltd. The production bases of Xinxing Cast Pipe (Xinjiang) Resources Development Co., Ltd. and Xinxing Cast Pipe Xinjiang Co., Ltd. have realized a market-oriented and domestic strategic layout focusing on product structure. At present, the company has a number of production bases such as Handan in Hebei, Wuhu in Anhui, Bazhou in Xinjiang, Huangshi in Hubei, Taojiang in Hunan, Chongzhou in Sichuan, etc., and 22 sales branches all over the country. Now it has become a comprehensive processing enterprise of metal products with an annual output of more than 10 million tons, forming a series of products such as emerging cast pipes, emerging steels, emerging special steel pipes, emerging gratings, emerging castings, emerging composite pipes and so on.

The company's centrifugal ductile iron pipe and steel grating production scale is large; With independent intellectual property rights, the world's first special steel pipe production technology fills the domestic gap; The main economic and technical indicators of the company's steel production process are in the forefront of the same industry in the country. The company's cast pipe production technology and product quality are at the world's leading level, and it is the world's largest supplier of centrifugal ductile iron pipes, with obvious competitive advantages, with a domestic market share of about 45% and an export ratio of about 30%, and its products are sold in more than 100 countries and regions. High-alloy and bimetallic composite pipe is a high-end product with independent intellectual property rights to fill the international gap, and it is the second fist product that the company is striving to create.

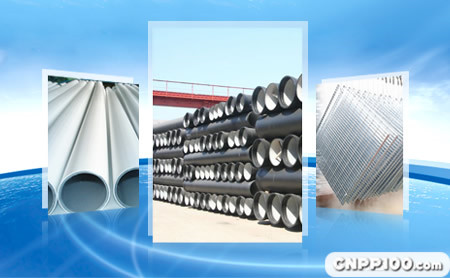

The company's main business is centrifugal ductile iron pipes and supporting pipe fittings, special steel pipes, steel smelting and rolling processing, casting products, etc., and currently has seven product series:

Xinxing cast pipe: production capacity of 1.8 million tons, diameter DN80 ~ DN3000mm, T-type, K-type, S-type, N1 type, self-anchored and other interface forms of ductile iron pipes are suitable for different terrain conditions, the use of cement mortar, polyurethane, epoxy ceramics and other anti-corrosion lined ductile iron pipes to meet different water quality transportation requirements, as well as zinc layer final decoration anti-corrosion layer, polyurethane and other outer wall anti-corrosion treatment technology ductile iron pipe is suitable for different corrosive soil environmental conditions, is an ideal pipe for urban water supply and gas transportation. The company presided over the formulation of the national standard of "Ductile Iron Pipes, Pipe Fittings and Accessories for Water and Gas Pipelines" (GB/T13295-2008).

Xinxing pipe fittings: with a production capacity of 40,000 tons, it is produced by shell type and original vacuum lost foam casting process, and various supporting pipe fittings can be developed and produced according to user needs to meet different construction conditions.

Xinxing Steel: With a production capacity of 8 million tons, it produces HRB335, HRB400, HRB500 and hot-rolled ribbed steel bars suitable for seismic resistance, round steel bars and excellent special steel products of Φ6~Φ32mm according to national standards.

Xinxing special steel pipe: with a production capacity of 180,000 tons, it mainly adopts centrifugal casting extrusion process, and produces high-end seamless steel pipe products such as bimetallic composite pipes and high-alloy steel pipes through extrusion and follow-up treatment of hollow raw material billets manufactured by centrifugal casting, which are used in petroleum and petrochemical, electric power, wear-resistant transportation and other industries.

Xinxing forgings: with a production capacity of 40,000 tons, using radial forging technology, it can produce alloy structural steel, high-quality carbon steel, alloy steel, stainless steel bars, thick-walled pipes, cast pipe molds, shafts, oil drill pipes and drilling, high alloy and special alloy forging billets. The products can be widely used in automobile, shipbuilding, wind power, thermal power, chemical industry, hydropower, metallurgical equipment and other industries.

Xinxing grating: with a production capacity of 80,000 tons, it is widely used in industrial platforms, escalators, fences, municipal, environmental protection facilities and other fields, and has significant advantages such as material saving, ventilation and light transmission, and easy installation compared with other materials used in the same category.

Xinxing steel-plastic pipe: with a production capacity of 3 million meters, it produces a full range of steel-plastic composite pipe products of Ф20~Ф200mm. The company presided over the formulation of the industry standard of "Steel-Plastic Composite Pressure Pipe" (CJ/T 183-2008), which solves the worldwide problem of steel-plastic degumming, with excellent performance, especially suitable for water supply and heating of high-rise buildings, as well as high-pressure liquid and gas transportation in food and chemical enterprises.

With the concept of "revitalizing the national pipeline industry", the company develops centrifugal ductile iron pipes and composite pipes with high quality, high speed and high level to contribute to the society and benefit mankind.